India has a large population and is the second most populous country in the world. With the development of the economy and the improvement of people's living standards, people's health awareness has gradually increased. They have begun to pay more attention to the nutrition and balance of their diet and pursue high-quality, nutritious food. dinner plates to meet the growing health needs, thus driving the growth in demand for high-quality dinner plates.

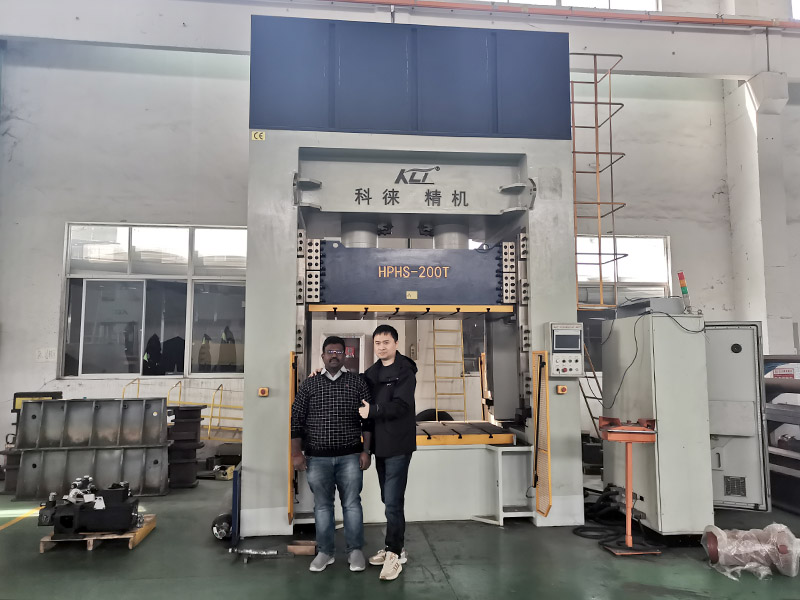

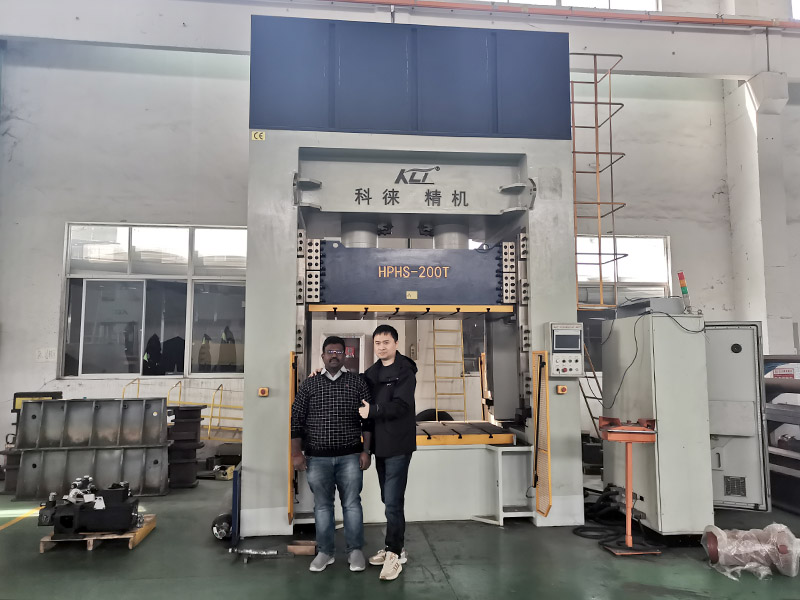

India Premier is a young and dynamic company that caters to the needs of various industrial fields and is committed to bringing world-class technology in the machine tool industry from the world to India and becoming a first-class solution provider in the Indian market. Our company and Indian Premier Company have started communicating on high-quality dinner plate projects since 2023, and reached cooperation at the beginning of this year.

There will be many problems and challenges in the production and future maintenance of the dinner plate production line:

1. Technical challenges: The dinner plate production line may involve complex manufacturing processes, including material selection, molding, printing, cutting, assembly, etc. Each link requires corresponding technical support and equipment, and it is also necessary to ensure smooth connection between these links.

2. Quality control: As food contact materials, the quality of dinner plates must meet strict safety standards. This requires strict quality control during the production process, including material inspection, process monitoring, finished product testing, etc.

3. Cost issue: The operation of the dinner plate production line requires a large amount of investment, including equipment purchase, raw material procurement, personnel training, maintenance, etc. At the same time, it is also necessary to consider how to improve production efficiency and reduce production costs to ensure the competitiveness of products.

4. Fluctuation in market demand: The market demand for dinner plates may be affected by various factors such as seasons, holidays, policies, etc., and there is great volatility. This requires the production line to have certain flexibility and adaptability to respond to changes in market demand.

In order to solve these difficulties, our company and our customers have jointly proposed a series of constructive measures to jointly respond to market challenges and technological changes:

1. Automation upgrade: If the production line has problems with insufficient manpower or complex operations, automation upgrade can be considered. For example, the introduction of automated equipment, such as robots, automated conveyor belts, etc., to reduce labor costs and improve production efficiency.

2. Quality control:

2.1 Establish a strict quality control system to monitor and test every link in the production process to ensure that product quality meets standards. At the same time, quality problems in the production process should be dealt with in a timely manner to prevent problems from expanding and affecting production efficiency.

2.2 Regularly maintain and maintain equipment on the production line to ensure normal operation and extend service life of the equipment. At the same time, equipment maintenance files are established to record and analyze the maintenance status of the equipment to discover and solve problems in a timely manner.

3. Process optimization: Optimize the production process, reduce production links and waiting time, and improve production efficiency. For example, optimize production plans, rationally arrange production batches and sequences, and avoid waste and duplication in the production process.

4. Information management: Introduce an information management system to conduct real-time monitoring and data analysis of the production process to help managers discover problems and make adjustments in a timely manner. At the same time, through data analysis, production plans and production processes are optimized to improve production efficiency.

In short, with the in-depth cooperation between the two parties, the Indian customer has achieved significant benefits in many aspects such as improving production efficiency, product quality, reducing production costs, expanding production capacity, optimizing resource management, enhancing market competitiveness, and promoting sustainable development. , thereby promoting the company's overall development and growth.