© 2023 Wuxi Kelai NC Machine Tool Co., Ltd. All rights reserved. Site Map

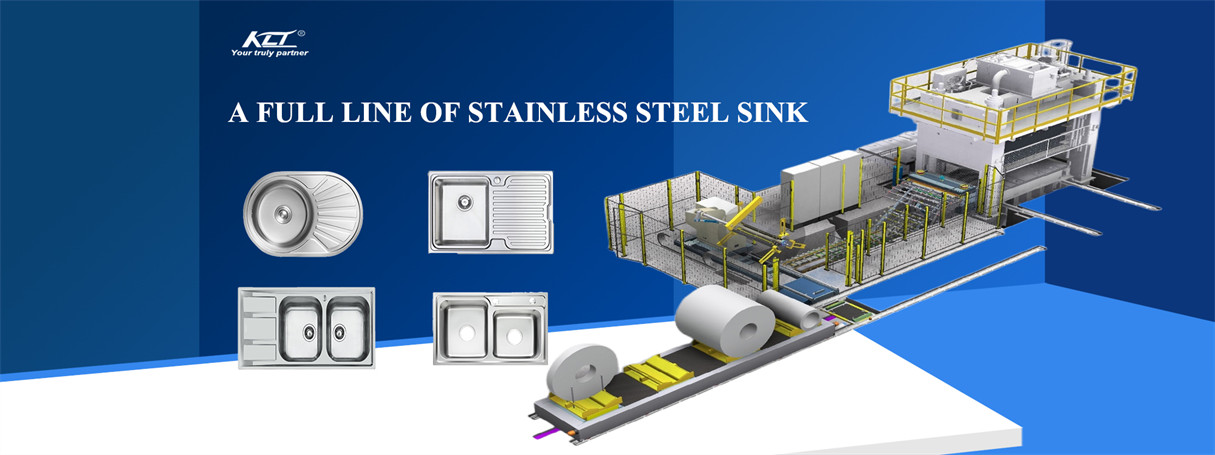

Feeding---Blanking---Stretching---Forming---Trimming---Flanging---Polishing---Cleaning.

You can choose between semi-automatic production lines and automated production lines. Semi-automatic production line: Stainless steel coils are purchased in batches for production. The equipment investment cost is low, man-machine integration, and quick results. It is suitable for investment in small-scale start-up factories. Adding manipulators and robots to the semi-automatic production line can achieve automated production with high output, stable product quality, fewer workers, and low overall cost of later use, making it suitable for medium- and large-scale factory investment.